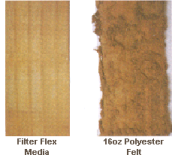

Filter Media

We offer a wide range of exclusive products. We ship only the highest quality media to our valued customers.

Patented Loop Pile Surface

Drum Filter Media manufactures the patented Beane Bag™ media. The Beane Bag™ media is circular knit fabric consisting of a patented "loop pile" surface. The circular knit process provides a high permeability, reducing pressure drop conditions with excellent filtration efficiencies of 99.5 to 99.99%. The physical movement of the "loop pile" surface on the cleaning cycle easily removes heavy dust formations while preventing blinding or plugging of the fabric. By eliminating the seam you have additional filter area and increased air flow. Diameters include 3.5", 4.7", 5", 6" 8", 9", 9.5", 12.5", 13" and 24". We also manufacture flat width fabric for large diameter filter media.

Superior Cleaning Action

The Beane Bag™ can be used in your baghouse system regardless of the bag cleaning method employed (i.e. Pulse-Jet, Shaker or Reverse Air) Bag cleaning energy is transmitted to

the self-cleaning loop pile structure on the dust side of the Beane Bag™ . The unique flexing action of the loop pile dust surface is designed to break up the accumulated dust

cake and discharge it efficiently in seconds, not minutes. Time and cleaning energy are saved. In addition wear and tear on both filter bags and bag cleaning mechanisms is minimized.

Energy Savings

With the increasing cost of electricity, energy savings are becoming more important. The Beane Bag™ helps to correct and reduce the high pressure drop conditions across the

baghouse system resulting in fan energy savings that could be substantial

Static Eliminator

Knitting with electrically conductive carbonized yarns, the media can improve baghouse safety by constantly drawing off static charges to ground. These fabrics will also combat "Static Cling" or

serious cases of dust hang up due to opposing static charges between the dust and the filter media.

|

Benefits

|

At Drum Filter Media we have over 20 years of experience manufacturing media for a variety of filters including the energy efficient Beane Bag™ . The design of the Beane Bag™ media has many advantages including: